Most fertigation systems used in cannabis today were never designed for cannabis. They were built for Big Ag crops like corn, lettuce and large field production—plants that don’t rely on precise multi-part nutrient recipes, milliliter accurate dosing or crop steering strategies. When cannabis cultivators try to retrofit those systems, the results are predictable: oversized batch tanks, inconsistent nutrient delivery, excessive labor and constant troubleshooting that slows down an entire grow.

Nik McCalligan, founder of Eden Water Technologies, saw this problem up close. After decades in water treatment and more than ten years inside cannabis facilities, he recognized the need for a truly purpose-built solution—systems engineered from the plant backward, not from traditional plumbing standards forward.

Nik McCalligan, founder of Eden Water Technologies, saw this problem up close. After decades in water treatment and more than ten years inside cannabis facilities, he recognized the need for a truly purpose-built solution—systems engineered from the plant backward, not from traditional plumbing standards forward.

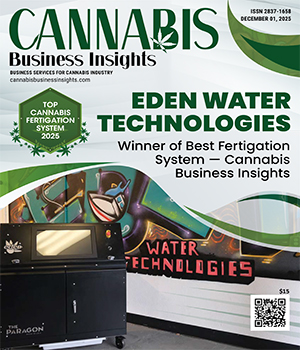

Paragon is the first fertigation system designed from the ground up specifically for cannabis cultivation. Every valve, pump, pipe and emitter is selected for one purpose: delivering the exact recipe each plant needs, on demand, with almost no intervention from staff. Its 18 injection points allow growers to run distinct nutrient strategies by zone while still operating on a single-header design.

“From our cannabis first design philosophy to the Paragon’s 99 percent dosing accuracy and plug and play simplicity, we’re redefining what growers should expect from a fertigation system and why so many never go back once they understand what we deliver,” says McCalligan.

A Complete Fertigation, Water Treatment and Piping Solution Built for Cannabis

Eden Water Tech’s value doesn’t come from a single machine. It comes from a connected design approach where water treatment, nutrient delivery, piping layout and irrigation all work together as one continuous process created specifically for cannabis. Instead of piecing together equipment from multiple vendors and hoping everything syncs, Eden delivers a complete fertigation and water treatment system engineered to function as a unified solution.

Each project begins long before installation. The team reviews facility plans, plant counts, cultivar strategies and irrigation preferences. From there we build a custom 3D model showing exactly how water and nutrients will move through the building. Every pipe, turn and feed pathway is visualized so growers can walk their design digitally and understand the flow before equipment arrives.

Each project begins long before installation. The team reviews facility plans, plant counts, cultivar strategies and irrigation preferences. From there we build a custom 3D model showing exactly how water and nutrients will move through the building. Every pipe, turn and feed pathway is visualized so growers can walk their design digitally and understand the flow before equipment arrives.

Eden handles water treatment, nutrient delivery, irrigation hardware and turnkey installation. Reverse osmosis systems, softeners, carbon skids, UV sanitization, nanobubbles and custom piping are selected based on plant requirements and facility goals. Nothing is off the shelf, and nothing is overbuilt. Every design is tailored with clarity and purpose, not unnecessary complexity.

This integrated approach is what simplifies operations downstream. Each part of the system is engineered to support the next. Water treatment feeds the Paragon. The Paragon feeds the single header. And the single header delivers consistent results to each zone with even distribution and without pressure fluctuations. Because everything is designed together, the system behaves predictably in real cultivation conditions.

This integrated approach is what simplifies operations downstream. Each part of the system is engineered to support the next. Water treatment feeds the Paragon. The Paragon feeds the single header. And the single header delivers consistent results to each zone with even distribution and without pressure fluctuations. Because everything is designed together, the system behaves predictably in real cultivation conditions.

For growers, the benefit is simple. They no longer deal with mismatched fittings, incompatible software or vendors blaming one another.

“Our solution behaves like a single organism that does one job exceptionally well,” says McCalligan. “It treats every gallon of water the same way, mixes nutrients on target and sends consistent feed to every plant, every cycle.”

Efficiency That Frees Space, Time and Capital

Cultivators are often surprised by how quickly operational drag disappears after adopting Eden’s system. Efficiency is a natural result of engineering choices that remove bottlenecks. By eliminating excessive piping headers, spider manifolds and redundant hardware, Eden frees valuable space and removes hidden labor that typically weighs down a cultivation facility.

The compact footprint is a quiet advantage across facilities of all sizes. A fertigation system occupying eight square feet can replace entire rooms of batch tanks, plumbing and electrical infrastructure. Reclaimed space becomes workstations, open hallways or even added canopy.

Time savings follow. A system that doesn’t require constant recalibration or tank cleaning changes the rhythm of a team’s workweek. Staff previously tied up measuring, mixing and troubleshooting can redirect their time to higher value tasks.

Time savings follow. A system that doesn’t require constant recalibration or tank cleaning changes the rhythm of a team’s workweek. Staff previously tied up measuring, mixing and troubleshooting can redirect their time to higher value tasks.

Capital efficiency improves too. Eden’s single-header design uses fewer materials, fewer valves and less labor. Installations that once took weeks can be completed much faster. Smaller pipe volumes reduce nutrient waste and allow facilities to start feeding sooner. Many facilities recover their investment in under a year.

Accuracy as a Performance Driver

Cultivation depends on consistency, and this is where Eden’s precision becomes a strategic advantage. Cannabis requires nutrient delivery that stays true to target, and the Paragon protects that margin. While industry tolerance often swings fifteen percent in either direction, Eden targets accuracy within about one percent. Stable recipes produce stable plant responses. Reliable delivery allows growers to run confident crop steering strategies without compensating for irregular feeds.

Simplicity and Low Maintenance by Design

Eden Water Tech builds systems so operators don’t spend their days fixing equipment. Routine upkeep is minimal and easy to teach. Installs move quickly: roughly a week on site, one day of training and plants feeding by day eight. The interface eliminates unnecessary steps so new staff can learn quickly.

Eden Water Tech builds systems so operators don’t spend their days fixing equipment. Routine upkeep is minimal and easy to teach. Installs move quickly: roughly a week on site, one day of training and plants feeding by day eight. The interface eliminates unnecessary steps so new staff can learn quickly.

Maintenance is simple and clearly divided.

Paragon maintenance: occasional pump tube replacements and basic checks.

Water treatment maintenance: quarterly filters, an annual UV bulb and standard monitoring.

Because components are simple and service calls are rare, growers can focus on the canopy instead of the water room.

Return on Investment That Shows Up Quickly

Installation requires fewer materials, fewer labor hours and much less electrical infrastructure than bulkier systems. Eden’s single-header design can significantly reduce piping, pumps, outlets and monitoring points, and smaller pipe volumes cut nutrient waste.

Installation requires fewer materials, fewer labor hours and much less electrical infrastructure than bulkier systems. Eden’s single-header design can significantly reduce piping, pumps, outlets and monitoring points, and smaller pipe volumes cut nutrient waste.

“Once operational, the ongoing savings compound. Precise dosing prevents nutrient waste, on demand feeds reduce water and energy use and eliminating tank cleaning removes recurring labor,” says McCalligan.

Many facilities see full ROI in under a year because efficiency touches every part of the operation.

Results in Real Facilities

At Green and Gold in Las Vegas, the Paragon replaced a complex, space heavy setup that never delivered the consistency the team needed. The cleaner footprint allowed operators to reclaim work areas, eliminate manual dosing and achieve more uniform plant behavior.

At Desert Evolution, the Paragon became one of the least labor-intensive parts of the facility. Operators check in as needed, but its reliability allows the team to focus on plant care instead of troubleshooting.

A Customer First Culture

What keeps cultivators with Eden Water Tech across multiple facilities isn’t just the equipment—it’s the partnership. We prioritize clarity, communication and practical guidance. We don’t push equipment growers don’t need. We focus on solutions that support long term success.

What keeps cultivators with Eden Water Tech across multiple facilities isn’t just the equipment—it’s the partnership. We prioritize clarity, communication and practical guidance. We don’t push equipment growers don’t need. We focus on solutions that support long term success.

Support is direct and accessible. Whether growers prefer phone support, video walkthroughs or in person training, Eden responds quickly. When a cultivator reaches out, they speak with someone who understands both water systems and cannabis cultivation. This steady, reliable support is a cornerstone of our reputation.

What Comes Next

With the Paragon firmly established, Eden Water Tech is expanding remote visibility and centralized management. The goal is to give growers a clearer window into how water and nutrient delivery behave across multiple facilities without adding complexity. Upcoming cloud tools will allow a single operator to manage several Paragon systems across different states.

As the industry shifts toward multisite cultivation, the company stays dedicated to delivering accuracy, efficiency and ease of use that scales with every facility.

Nik McCalligan, founder of Eden Water Technologies, saw this problem up close. After decades in water treatment and more than ten years inside cannabis facilities, he recognized the need for a truly purpose-built solution—systems engineered from the plant backward, not from traditional plumbing standards forward.

Nik McCalligan, founder of Eden Water Technologies, saw this problem up close. After decades in water treatment and more than ten years inside cannabis facilities, he recognized the need for a truly purpose-built solution—systems engineered from the plant backward, not from traditional plumbing standards forward.Paragon is the first fertigation system designed from the ground up specifically for cannabis cultivation. Every valve, pump, pipe and emitter is selected for one purpose: delivering the exact recipe each plant needs, on demand, with almost no intervention from staff. Its 18 injection points allow growers to run distinct nutrient strategies by zone while still operating on a single-header design.

Our solution behaves like a single organism that does one job exceptionally well. It treats every gallon of water the same way, mixes nutrients on target and sends consistent feed to every plant, every cycle.

A Complete Fertigation, Water Treatment and Piping Solution Built for Cannabis

Eden Water Tech’s value doesn’t come from a single machine. It comes from a connected design approach where water treatment, nutrient delivery, piping layout and irrigation all work together as one continuous process created specifically for cannabis. Instead of piecing together equipment from multiple vendors and hoping everything syncs, Eden delivers a complete fertigation and water treatment system engineered to function as a unified solution.

Each project begins long before installation. The team reviews facility plans, plant counts, cultivar strategies and irrigation preferences. From there we build a custom 3D model showing exactly how water and nutrients will move through the building. Every pipe, turn and feed pathway is visualized so growers can walk their design digitally and understand the flow before equipment arrives.

Each project begins long before installation. The team reviews facility plans, plant counts, cultivar strategies and irrigation preferences. From there we build a custom 3D model showing exactly how water and nutrients will move through the building. Every pipe, turn and feed pathway is visualized so growers can walk their design digitally and understand the flow before equipment arrives.Eden handles water treatment, nutrient delivery, irrigation hardware and turnkey installation. Reverse osmosis systems, softeners, carbon skids, UV sanitization, nanobubbles and custom piping are selected based on plant requirements and facility goals. Nothing is off the shelf, and nothing is overbuilt. Every design is tailored with clarity and purpose, not unnecessary complexity.

This integrated approach is what simplifies operations downstream. Each part of the system is engineered to support the next. Water treatment feeds the Paragon. The Paragon feeds the single header. And the single header delivers consistent results to each zone with even distribution and without pressure fluctuations. Because everything is designed together, the system behaves predictably in real cultivation conditions.

This integrated approach is what simplifies operations downstream. Each part of the system is engineered to support the next. Water treatment feeds the Paragon. The Paragon feeds the single header. And the single header delivers consistent results to each zone with even distribution and without pressure fluctuations. Because everything is designed together, the system behaves predictably in real cultivation conditions.For growers, the benefit is simple. They no longer deal with mismatched fittings, incompatible software or vendors blaming one another.

“Our solution behaves like a single organism that does one job exceptionally well,” says McCalligan. “It treats every gallon of water the same way, mixes nutrients on target and sends consistent feed to every plant, every cycle.”

Efficiency That Frees Space, Time and Capital

Cultivators are often surprised by how quickly operational drag disappears after adopting Eden’s system. Efficiency is a natural result of engineering choices that remove bottlenecks. By eliminating excessive piping headers, spider manifolds and redundant hardware, Eden frees valuable space and removes hidden labor that typically weighs down a cultivation facility.

-

From our cannabis first design philosophy to the Paragon’s 99 percent dosing accuracy and plug and play simplicity, we’re redefining what growers should expect from a fertigation system and why so many never go back once they understand what we deliver.

The compact footprint is a quiet advantage across facilities of all sizes. A fertigation system occupying eight square feet can replace entire rooms of batch tanks, plumbing and electrical infrastructure. Reclaimed space becomes workstations, open hallways or even added canopy.

Time savings follow. A system that doesn’t require constant recalibration or tank cleaning changes the rhythm of a team’s workweek. Staff previously tied up measuring, mixing and troubleshooting can redirect their time to higher value tasks.

Time savings follow. A system that doesn’t require constant recalibration or tank cleaning changes the rhythm of a team’s workweek. Staff previously tied up measuring, mixing and troubleshooting can redirect their time to higher value tasks. Capital efficiency improves too. Eden’s single-header design uses fewer materials, fewer valves and less labor. Installations that once took weeks can be completed much faster. Smaller pipe volumes reduce nutrient waste and allow facilities to start feeding sooner. Many facilities recover their investment in under a year.

Accuracy as a Performance Driver

Cultivation depends on consistency, and this is where Eden’s precision becomes a strategic advantage. Cannabis requires nutrient delivery that stays true to target, and the Paragon protects that margin. While industry tolerance often swings fifteen percent in either direction, Eden targets accuracy within about one percent. Stable recipes produce stable plant responses. Reliable delivery allows growers to run confident crop steering strategies without compensating for irregular feeds.

Simplicity and Low Maintenance by Design

Eden Water Tech builds systems so operators don’t spend their days fixing equipment. Routine upkeep is minimal and easy to teach. Installs move quickly: roughly a week on site, one day of training and plants feeding by day eight. The interface eliminates unnecessary steps so new staff can learn quickly.

Eden Water Tech builds systems so operators don’t spend their days fixing equipment. Routine upkeep is minimal and easy to teach. Installs move quickly: roughly a week on site, one day of training and plants feeding by day eight. The interface eliminates unnecessary steps so new staff can learn quickly. Maintenance is simple and clearly divided.

Paragon maintenance: occasional pump tube replacements and basic checks.

Water treatment maintenance: quarterly filters, an annual UV bulb and standard monitoring.

Because components are simple and service calls are rare, growers can focus on the canopy instead of the water room.

Return on Investment That Shows Up Quickly

Installation requires fewer materials, fewer labor hours and much less electrical infrastructure than bulkier systems. Eden’s single-header design can significantly reduce piping, pumps, outlets and monitoring points, and smaller pipe volumes cut nutrient waste.

Installation requires fewer materials, fewer labor hours and much less electrical infrastructure than bulkier systems. Eden’s single-header design can significantly reduce piping, pumps, outlets and monitoring points, and smaller pipe volumes cut nutrient waste. “Once operational, the ongoing savings compound. Precise dosing prevents nutrient waste, on demand feeds reduce water and energy use and eliminating tank cleaning removes recurring labor,” says McCalligan.

Many facilities see full ROI in under a year because efficiency touches every part of the operation.

Results in Real Facilities

At Green and Gold in Las Vegas, the Paragon replaced a complex, space heavy setup that never delivered the consistency the team needed. The cleaner footprint allowed operators to reclaim work areas, eliminate manual dosing and achieve more uniform plant behavior.

At Desert Evolution, the Paragon became one of the least labor-intensive parts of the facility. Operators check in as needed, but its reliability allows the team to focus on plant care instead of troubleshooting.

A Customer First Culture

What keeps cultivators with Eden Water Tech across multiple facilities isn’t just the equipment—it’s the partnership. We prioritize clarity, communication and practical guidance. We don’t push equipment growers don’t need. We focus on solutions that support long term success.

What keeps cultivators with Eden Water Tech across multiple facilities isn’t just the equipment—it’s the partnership. We prioritize clarity, communication and practical guidance. We don’t push equipment growers don’t need. We focus on solutions that support long term success. Support is direct and accessible. Whether growers prefer phone support, video walkthroughs or in person training, Eden responds quickly. When a cultivator reaches out, they speak with someone who understands both water systems and cannabis cultivation. This steady, reliable support is a cornerstone of our reputation.

What Comes Next

With the Paragon firmly established, Eden Water Tech is expanding remote visibility and centralized management. The goal is to give growers a clearer window into how water and nutrient delivery behave across multiple facilities without adding complexity. Upcoming cloud tools will allow a single operator to manage several Paragon systems across different states.

As the industry shifts toward multisite cultivation, the company stays dedicated to delivering accuracy, efficiency and ease of use that scales with every facility.

Thank you for Subscribing to Cannabis Business Insights Weekly Brief