The cannabis industry faces a new hurdle: price compression due to a surge in producers. This fierce competition erodes manufacturers' profits, demanding a strategic response. Businesses must meticulously analyze and minimize manufacturing costs to remain viable.

SciPhy Systems, a technology and consulting firm, understands this challenge. They empower clients to navigate this competitive landscape by optimizing production costs and achieving market competitiveness without compromising quality. They provide innovative technology solutions alongside strategic insights to maximize efficiency in manufacturing cannabis extracts, isolates, and edibles.

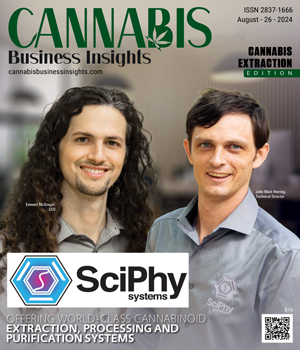

“For almost a decade, the essence of our business existence has been to design, manufacture, and purvey highly customized and high-tech cannabis extraction, processing, and purification systems. We pair our equipment with consulting services to support visionary companies' efforts to streamline and enhance the efficiency of their production facilities at the appropriate scale for this competitive market,” says Emmett McGregor, CEO of SciPhy Systems.

The company’s product portfolio contains five types of processing systems for the cannabis industry. They offer integrated and automated hydrocarbon extractors that use butane and propane to extract oils. SciPhy Systems provides a cost-efficient solution that surpasses other solvents in the market for both cost and quality of oil produced. This solution extends beyond extraction, providing a suite of specialized and integrated post-processing tools. These tools empower companies to manufacture high-quality output oil with minimal energy and material costs. Its comprehensive product line commences with the HVH-50 50 lb. per hour extractor for butane extraction, soon expanding with additional compact models featuring their patented Symphase heat management system, which eliminates the need for electricity-hungry heaters and chillers. Following that, SciPhy Systems has introduced the Hydrocarbon Membrane System (HMS), designed for color remediation, dewaxing, and separation of High Terpene Extract from broad extract oil. For manufacturers entering the specialty ingredient market, it deploys the membrane-based Zaiput multi-stage countercurrent liquid-liquid extraction (CC-LLE) separator platform, which excels in cannabinoid separations and other purifications.

“Our company is built on innovation in cannabis processing,” said Technical Director John Mark Herring. “The HVH-50 is a product of that drive and holds key new innovative components that can have a lasting impact on both cannabis and other industries.”

Additionally, companies that use ethanol and heavy hydrocarbon solvents to enhance their operational efficiency can benefit from the X-spiral line of spiral-wound membrane-based filter systems. They enable dewaxing, decoloring, and solvent remediation with exceptional energy efficiency, helping them to save up to 99 percent of electricity compared to alternate systems. This reduces manufacturing costs and allows customers to qualify for energy incentives from utilities or local power districts, making the adoption of new technologies more cost-effective for their processes across various product lines.

One distinguishing aspect of SciPhy Systems is its commitment to a white-glove service approach, integrating expertise into business planning and manufacturing line analysis, which has garnered client appreciation. It has also received valuable feedback from numerous customers who credit its technology for helping them survive and prosper in competitive markets as well as expand their businesses. In instances where previous technologies were too expensive to maintain profitability, the company’s solutions have provided a lifeline, enabling growth and success for its clients. Some customers have undergone retrofits to optimize their operations and achieve thriving outcomes. Individuals who have learned the importance of understanding manufacturing costs after teaming up with SciPhy Systems have become highly competitive in their markets.

SciPhy Systems emerged from the founders’ backgrounds in fine chemical manufacturing, later pivoting to serve the cannabis industry, initially offering consulting and procurement services for cannabis companies. With a focus on advocacy and efficiency, it evolved into a leader in extraction technology, designing and distributing high-quality and engineered-to-suit products. By championing the cause of energy-efficient equipment and demonstrating its positive impact on businesses, this pioneering company is committed to sustainability and making sound business sense, resulting in cost savings and increased profits for clients.

To reach out to Emmett, John, and the SciPhy team click here: https://sciphysystems.com/

SciPhy Systems, a technology and consulting firm, understands this challenge. They empower clients to navigate this competitive landscape by optimizing production costs and achieving market competitiveness without compromising quality. They provide innovative technology solutions alongside strategic insights to maximize efficiency in manufacturing cannabis extracts, isolates, and edibles.

“For almost a decade, the essence of our business existence has been to design, manufacture, and purvey highly customized and high-tech cannabis extraction, processing, and purification systems. We pair our equipment with consulting services to support visionary companies' efforts to streamline and enhance the efficiency of their production facilities at the appropriate scale for this competitive market,” says Emmett McGregor, CEO of SciPhy Systems.

The company’s product portfolio contains five types of processing systems for the cannabis industry. They offer integrated and automated hydrocarbon extractors that use butane and propane to extract oils. SciPhy Systems provides a cost-efficient solution that surpasses other solvents in the market for both cost and quality of oil produced. This solution extends beyond extraction, providing a suite of specialized and integrated post-processing tools. These tools empower companies to manufacture high-quality output oil with minimal energy and material costs. Its comprehensive product line commences with the HVH-50 50 lb. per hour extractor for butane extraction, soon expanding with additional compact models featuring their patented Symphase heat management system, which eliminates the need for electricity-hungry heaters and chillers. Following that, SciPhy Systems has introduced the Hydrocarbon Membrane System (HMS), designed for color remediation, dewaxing, and separation of High Terpene Extract from broad extract oil. For manufacturers entering the specialty ingredient market, it deploys the membrane-based Zaiput multi-stage countercurrent liquid-liquid extraction (CC-LLE) separator platform, which excels in cannabinoid separations and other purifications.

“Our company is built on innovation in cannabis processing,” said Technical Director John Mark Herring. “The HVH-50 is a product of that drive and holds key new innovative components that can have a lasting impact on both cannabis and other industries.”

For almost a decade, the essence of our business existence has been to design, manufacture, and purvey highly customized and high-tech cannabis extraction, processing, and purification systems. We pair our equipment with consulting services to support visionary companies' efforts to streamline and enhance the efficiency of their production facilities at the appropriate scale for this competitive market

Additionally, companies that use ethanol and heavy hydrocarbon solvents to enhance their operational efficiency can benefit from the X-spiral line of spiral-wound membrane-based filter systems. They enable dewaxing, decoloring, and solvent remediation with exceptional energy efficiency, helping them to save up to 99 percent of electricity compared to alternate systems. This reduces manufacturing costs and allows customers to qualify for energy incentives from utilities or local power districts, making the adoption of new technologies more cost-effective for their processes across various product lines.

One distinguishing aspect of SciPhy Systems is its commitment to a white-glove service approach, integrating expertise into business planning and manufacturing line analysis, which has garnered client appreciation. It has also received valuable feedback from numerous customers who credit its technology for helping them survive and prosper in competitive markets as well as expand their businesses. In instances where previous technologies were too expensive to maintain profitability, the company’s solutions have provided a lifeline, enabling growth and success for its clients. Some customers have undergone retrofits to optimize their operations and achieve thriving outcomes. Individuals who have learned the importance of understanding manufacturing costs after teaming up with SciPhy Systems have become highly competitive in their markets.

SciPhy Systems emerged from the founders’ backgrounds in fine chemical manufacturing, later pivoting to serve the cannabis industry, initially offering consulting and procurement services for cannabis companies. With a focus on advocacy and efficiency, it evolved into a leader in extraction technology, designing and distributing high-quality and engineered-to-suit products. By championing the cause of energy-efficient equipment and demonstrating its positive impact on businesses, this pioneering company is committed to sustainability and making sound business sense, resulting in cost savings and increased profits for clients.

To reach out to Emmett, John, and the SciPhy team click here: https://sciphysystems.com/

Company : SciPhy Systems

Headquarters :

. ManagementEmmett McGregor, CEO; John Mark Herring, Technical Director

Thank you for Subscribing to Cannabis Business Insights Weekly Brief